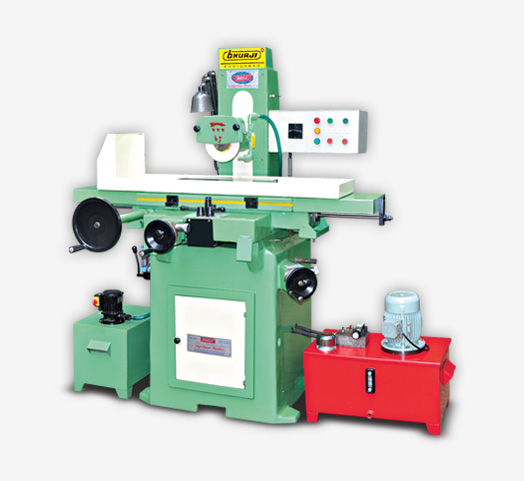

High precision spindle with 110mm Dia and high class Double Row Breaings (front & back) for greater accuracy and finish. The spindle is supported by Heavy Duty Design Honey-Combed Pillar for stability to larger dia and width of grinding wheel while working.

High precision Ball Screw for cross movement and optional for vertical movement ensures higher acuracy, free movement and long life.

Special Auto Lubrication System increase the life of all sliding parts and screws. Advanced hydraulic system with independent oil tank is placed outside the machine to eleminate heat & vibration.

Equipped with LM GuideWays in verical column for precise positionin, low wear & tear. It helps in aintaining higher accuracy for a prolonged time.

Extra Large Bed Base in length & width in comparison to work table ensures no overhang of table during grinding conditions. Double V Ways cross guide gives maximm stability and accuracy.

Micro Feed Hydraulic Surface Grinders are robust and simple in design but accurate and efficient, as well as most suitable for the tool room and production jobs. The Cross Slide is on Double-V which is best for Hydraulic Surface Grinding Machines for rigidity and stability.

Our Surface Grinding Machines are fitted with Compact Hydraulic Power Pack (dust proof) with an exclusively designed control unit incorporated within the body of machine. The said system does not require any extra load. The required pressure-oil drains through a fine filter, before entering the Tank. The Hydraulic Tank is fitted outside to eliminate any heat and vibrations.

Ultra precision hardened Nitralloy Spindle (grease packed for long life) runs in antifriction bearings and directly driven by flange mounted motor (to eliminate any vibration) through flexible couplings. Its production and testing passes through rigorous inspection at manufacturing stages to ensure smooth and trouble free running and sensitivity essential for extra ordinary finish. The Spindle housing is supported in Vertical Column which is heavy duty, ribbed and stationary.

The Magnetic Table travels on ´Vee & Flat Guide-way´ and is driven through a hydraulic cylinder, having provision of continuous lubrication. The Cross Movement is on Double V Guide-ways through Electric Motor for fine and incremental grinding.

| Model | A-818 |

|---|---|

| Max. Table Grinding | 200 x 450 |

| Max. Magnetic Table Travel | 250 x 500 |

| Magnetic Chuck Suitable (optional) | 200 x 450 |

| Max. Grinding Height under Wheel | 225 |

| Grinding Wheel Head Motor Speed | 2800 rpm |

| Grinding Wheel Head Motor | 1 HP - 3 phase |

| Hyraulic Tank Capacity (Telus - 68) | 35 Ltrs. |

| Hydraulic Pump Motor | 1 HP |

| Auto Gross Feed Increment (Motorised Model Only) | 0.2 - 5.0 |

| Max. Longitudinal Table Speed | 15 M/min |

| Vertical Feed Graduation | 0.01 |

| Cross Feed Graduation | 0.05 |

| Working Pressure | 12 Kg/cm2 |

| Min. Vertical Feed Graduation | 0.01 |

| Net Weight | 1100 Kg |

| Wooden Case Dimension (L x W x H) | 1050 x 1500 x 1700 |

Note: For constant development we reserve the rights to change any technical specifications and design without prior notice.