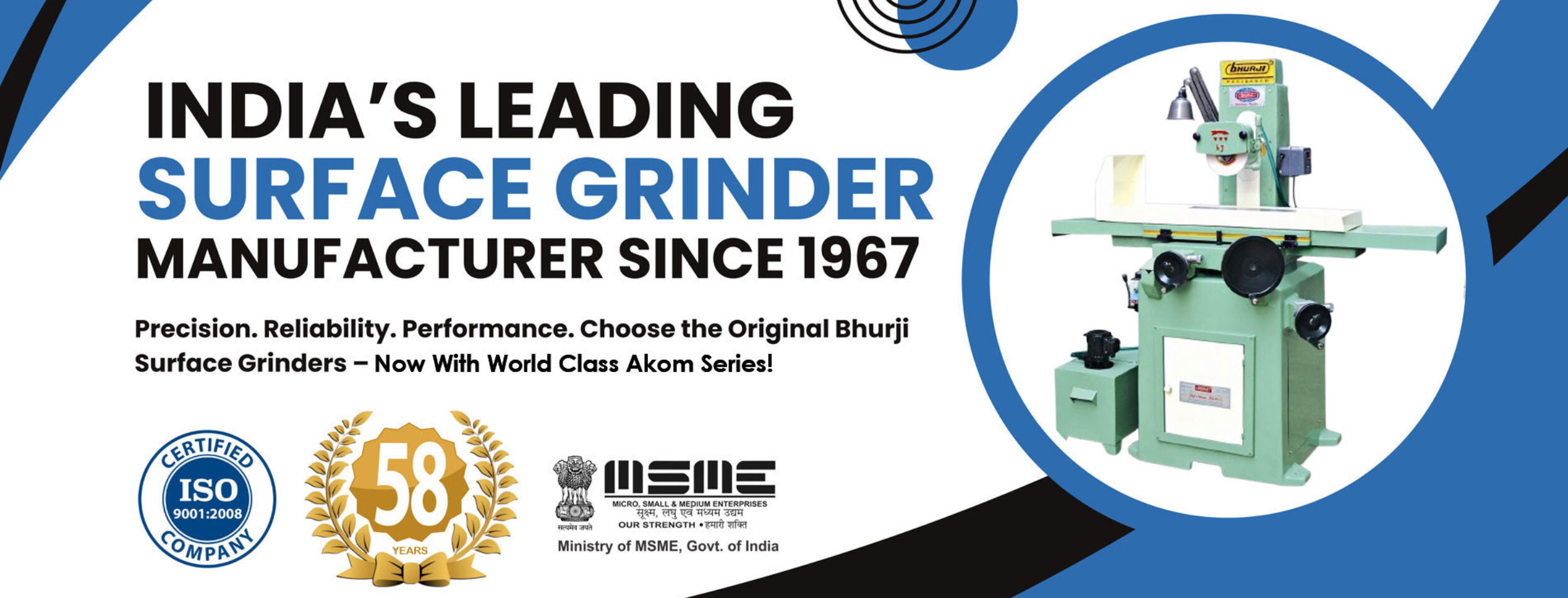

Surface grinding plays a crucial role in achieving high-precision finish surfaces for metal components manufacturing processes. In productivity, quality, and cost efficiency. In this comprehensive guide, we will explore the differences between manual and hydraulic surface grinders machine. We will discuss manual and hydraulic surface grinders working principles, key features, benefits, limitations, and ideal applications. By the end, you will be equipped with all the information you need to decide which type best meets and fulfills your production requirements.

How Surface Grinders Machine Works

Surface grinders use a rotating abrasive wheel to remove material from a workpiece. The process involves several critical parameters, such as:

- Wheel speed moving: The speed at which the grinding wheel rotates.

- Feed rate ratio: The speed at which the workpiece is fed under the grinding wheel.

- Depth of cut of components: The thickness of the material removed in one pass.

The precision of these variables determines the quality of the finish and the accuracy of the dimensions.

Are manual Surface Grinders the Best for you?

Manual Working Overview

Manual surface grinders are traditional machines that require an operator to control the grinding process by manually. These machines are known for their simple direct control, making them a favorite in workshops where precision and craftsmanship are highly valued.

Manual Grinder Working Principle

The working principle of a manual surface grinder is simple straightforward. The operator adjusts the machine settings—such as the position of the workpiece and the speed of the wheel—and then manually the workpiece through the grinding process. The operator must monitor the operation, making adjustments to ensure the workpiece meets the required need specifications.

Manual Surface Grinder Features

- Direct Control by Optrater: Operators have hands-on control over the grinding process.

- Simplicity as Star the Machine: The mechanical design is simpler compared to hydraulic systems, making them easier to repair and maintain.

- Cost-Effectiveness to allow your pocket: Typically, manual machines have a lower initial cost compared to their hydraulic counterparts.

- Versatility of Usecase: Suitable for custom, small-batch work where detailed operator input is crucial.

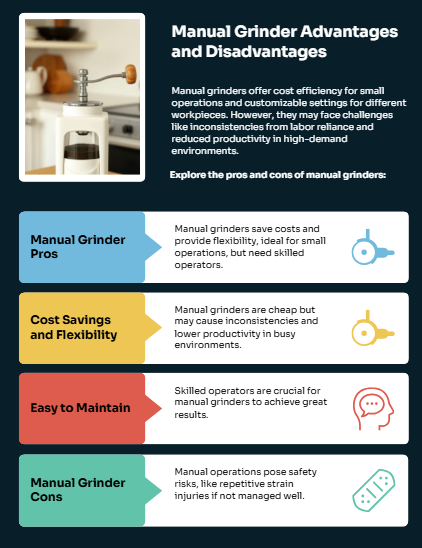

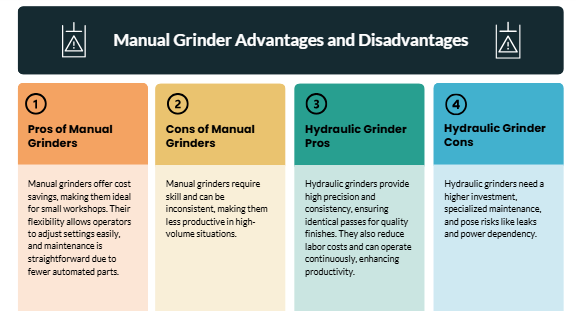

Manual Grinder Advantages and Disadvantages

Advantages

- Cost Savings Low burget: Lower capital expenditure makes manual surface grinders an attractive option for small workshops or start-up businesses.

- Flexibility to use : Operators can easily adapt the machine settings for different types of workpieces.

- Ease of Maintenance machine: With fewer automated components, these machines are simpler to maintain and repair.

- Operator Skill Enhance: Highly skilled operators can produce exceptional results with manual machines.

Disadvantages

- Labor-Intensive: The process relies heavily on the operator’s skill and attention, which can lead to inconsistencies if not managed properly.

- Lower Productivity is high: Manual operation may reduce throughput, particularly in high-volume production environments.

- Increased Human Error problem: The quality of the finish and precision of the workpiece may vary with operator performance.

- Safety Concerns increase: Continuous manual handling increases the risk of repetitive strain injuries and accidents if safety protocols are not strictly followed.

Manual Machines Applications

Manual surface grinders are best suited for:

- Small-Scale Production Industry: Ideal for custom jobs and prototypes where production volume is low.

- Repair and Maintenance Workshops Easy: Suitable for reconditioning worn parts or components.

- Educational Institutions : Used for training purposes to teach the fundamentals of grinding operations.

- High-Precision Tasks heavily: When the work requires a high level of human oversight for quality control.

Hydraulic Surface Grinders Working, Advantages and Disadvantages

Hydraulic Overview

Hydraulic surface grinders represent of grinding technology by incorporating hydraulic systems to control the movement of the grinding table. Allows for more precise adjustments, stability, and higher efficiency in the grinding process.

Hydraulic Working Main Principle

Hydraulic surface grinders hydraulic cylinders and motors to control the positioning of the grinding table and workpiece. This system enables smooth, vibration-free operation and reduces the reliance on manual adjustments. Hydraulic control systems can achieve movements, which is essential for tolerances and a superior surface finish.

Hydraulic main Features

- Automated Adjustments: Hydraulic controls allow for precise adjustments without manual intervention.

- Stability Work: The hydraulic system minimizes vibrations, ensuring a consistent finish.

- Efficiency Control: High throughput and minimal downtime due to automated operation.

- Enhanced Safety: Reduced operator intervention minimizes the risk of accidents and repetitive strain injuries.

- User-Friendly Controls: Modern hydraulic machines come with intuitive control panels and real-time monitoring systems.

Hydraulic Advantages and Disadvantages

Advantages

- Precision and Consistency is High: The hydraulic system ensures that every pass is identical, leading to consistent high-quality finishes.

- Reduced Labor Costs and Working Hours: Automation reduces the need for constant operator intervention, which can lower labor costs.

- Higher Productivity without Humans working: The machine can operate continuously with minimal adjustments, increasing overall throughput.

- Enhanced Safety with Machine: Fewer manual adjustments mean a safer working environment.

- Lower Operator : Automation leads to less physical strain on the operator, reducing the risk of errors due to fatigue.

Disadvantages

- Higher Initial Investment: The advanced technology used in hydraulic surface grinders can lead to higher upfront costs.

- Complexity: The hydraulic system requires specialized knowledge for troubleshooting and maintenance.

- Potential for Hydraulic Leaks: As with any hydraulic system, there is a risk of leaks, which can lead to downtime and additional maintenance.

- Dependence on Power Quality: These systems often require stable power supplies; fluctuations can affect performance.

Hydraulic Applications

Hydraulic surface grinders are best suited for:

- High-Volume Production: Ideal for mass production where consistency and efficiency are critical.

- Precision Engineering: Perfect for applications where tight tolerances are non-negotiable.

- Automated Manufacturing Lines: Integrates seamlessly into automated production environments.

- Industrial Environments: Suitable for heavy-duty operations in industries such as aerospace, automotive, and tooling.

Comparative Analysis: Manual vs. Hydraulic Surface Grinders

Below is a detailed comparison table summarizing the key differences between manual and hydraulic surface grinders:

| Parameter | Manual Surface Grinder | Hydraulic Surface Grinder |

|---|---|---|

| Operation Mode | Manual control by skilled operator | Automated hydraulic control system |

| Precision | Dependent on operator skill; high variability possible | High precision with consistent performance |

| Production Throughput | Lower throughput due to manual adjustments | Higher throughput with continuous automated operation |

| Initial Cost | Lower capital expenditure | Higher initial investment |

| Maintenance | Simpler mechanical components; easier DIY maintenance | Requires specialized technical skills for hydraulic system repair |

| Safety | Higher risk due to manual handling | Enhanced safety with reduced operator intervention |

| Flexibility | More adaptable for custom and one-off projects | Best for repetitive, high-volume production |

| Operator Fatigue | Increased risk due to continuous manual adjustments | Reduced fatigue due to automated operation |

| Learning Curve | Steeper; requires extensive operator training | More intuitive once set up, but requires technical understanding |

Cost Analysis and Maintenance of Surface Machine

Cost Analysis

When deciding between manual and hydraulic surface grinders, cost is a significant factor. While the initial investment for a manual surface grinder is generally lower, the costs of labor, longer production times, and potential variability can add up. In contrast, hydraulic surface grinders require a higher investment but offer long-term savings in terms of increased productivity and reduced labor costs.

Cost Considerations of Machine:

- Manage Purchase Price:

- Manual machines are more affordable in start.

- Hydraulic machines involve a higher capital end.

- Operational Costs of Surface Grinder Machine:

- Manual grinders demand more operator time.

- Hydraulic systems are automated, reducing costs over time.

- Maintenance Cost and Expenses:

- Manual grinders have fewer components and simpler repair work processes.

- Hydraulic systems require technical maintenance and may incur additional costs if hydraulic leaks or issues occur.

Maintenance Requirements of Surface Grinder Machine

Proper maintenance is critical for both manual and hydraulic surface grinders to give longevity and optimum performance.

- Manual Surface Grinders Maintainace:

- Regular cleaning and lubrication of mechanical components.

- Routine inspection of gears, bearings, and control mechanisms.

- Operator training to detect wear and tear early.

- Hydraulic Surface Grinders:

- Scheduled maintenance of hydraulic systems, including checking fluid levels and seals.

- Regular calibration of automated controls to maintain precision.

- Specialized service personnel may be required for complex repairs.

By investing in a well-structured maintenance program, manufacturers can maximize the lifespan of their equipment and minimize unexpected downtime.

Bhurji Surface Grinder is a trusted name in precision grinding machinery. Since 1967, we have been manufacturing high-quality surface grinders with ISO-certified accuracy. As a leading Surface Grinder Manufacturer in India and Surface Grinder Supplier in India, we provide reliable and durable machines for various industrial applications. Explore our range of manual, hydraulic, and CNC surface grinders designed for superior performance. Visit our website to find the perfect grinding solution for your needs.