The name Bhurji came into existence with the incorporation of Sr. Dilbar Singh and his son Sr. Balbir Singh Bhurji in 1967 as a small enterprise to cater the needs of machine tool in emerging Indian market and in the same year they had built its first Surface Grinder Machine with their utmost engineering expertise and dedicated efforts.

And that very first machine had given them a huge success in the market. Gradually the demand grew and the name Bhurji expanded its’ wings as a brand for the company named Injectman-Plastics in 1973, specifically dedicated to Surface Grinders only.

The success story continues and in 1982, the company introduced its first Hydraulic Surface Grinder under the guidance of mentor Sr. Balbir Singh Bhurji who was Mechanical Engineer.

Almost with the experience of two generations and six decade, the company’s quality standards and expertise has touched new peaks. Now the company is governed by third generation Mr. Vikram Singh Bhurji (B.Tech.) who has great experience and exposure of working with top companies like HMT and many more.

Under the vision of Mr. Vikram Singh Bhurji the company is constantly improving and upgrading its manufacturing standards to cater the demands of machine tool market and developed many new models in Surface Grinding Machines, Creep Feed Grinding Machines and SPM to furnish the requirements of both Indian & International markets. The company always intened to deliver high quality machines at competitive prices with total customer satisfaction.

Sr. Balbir Singh Bhurji

The FounderFrom the last few decades engineering industry has seen a major change in the genre of tooling, manufacturing and production. This was an era of modern machining and automation setups. The demand for high precision, ultra modern, advance machine tools are essentials to meet the standards of international markets.

The third successor of Bhurji abode, Mr. Vikram Singh Bhurji has felt this change of trend ways ahead. A striving enthusiast by nature and with prudent vision, he comes up with an all new brand, named AKOM in 2002. Akom SuperCut Series are a next level surface grinding machines that can withstand all the international standards of ultra modern machine tool needs.

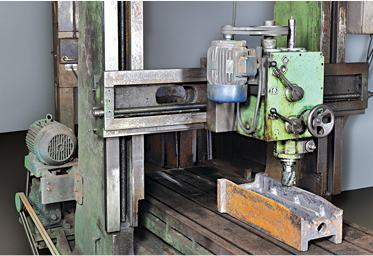

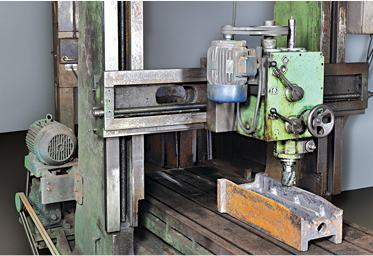

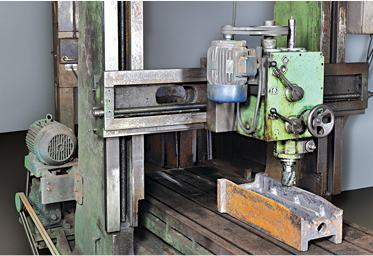

Akom SuperCut Series range of machines are specially designed on the principle of practicality and technical basics in order to give high class precision grinding fuctionality and are completely manufactured in its own well-equipped infrastructure unit located at Faridabad.

These machines have been developed keeping in mind the three basic concepts of stability, rigidity and accuracy. Plus a high precision quality output under much lesser time.

All the high end precision machines have a very basic and utmost rule of spindle stability which Akom SuperCut Series live up to with Stationery Pillar Design Concept, delivering higher finish with accuracy and is proven design for all the new CNCs and super precision machines.

Mr. Vikram Singh Bhurji

The Executive Director

Awarded at Machine Tool Exhibition, New Delhi - 1982

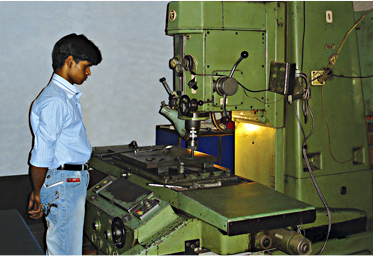

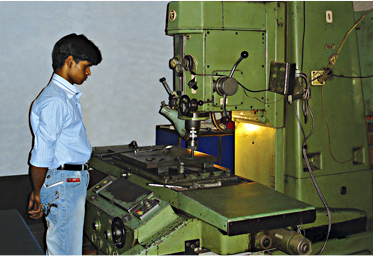

We have a fully dedicated and experienced team of qualified Engineers, Machinists, Scrapper Men and Fitters to assemble surface grinding machines. The entire work force is well trained and expert in their respective fields and are the real strength & pillars of our company in developing & manufacturing high precision surface grinders.

Machinists adhered to drawings and work at close tolerances so as to attain perfect quality standards in order to deliver high end surface grinders.

Fitters and Scrapping Men are well versed in assembling wide range of surface grinding machines with utmost precision and accuracy all the time. Also they are given periodic training, to be well-versed with latest techniques and technology for the assembling of high precision surface grinders.

QC persons constantly assist the technical team at every stage of manufacturing in order to build very high precision surface grinding machine flawlessly and smoothly with all the high tech equipment and latest alignment technology to check the machine assembled at every stage.

They have a widespread of distribution network across the nations to market and deliver the surface grinding machines with total customer satisfaction and after sales support.