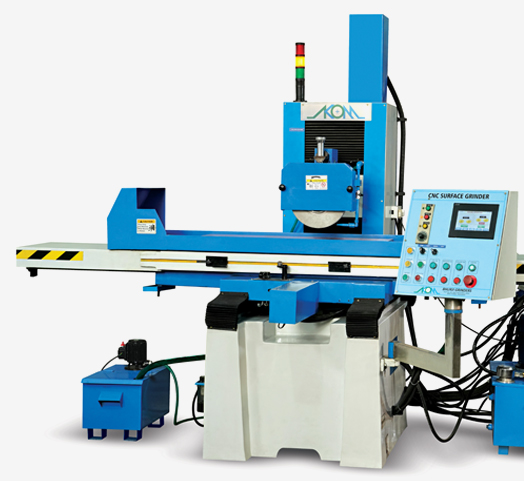

Affordable and easy to operate AKOM CNC Surface Grinding Machines are designed and built for accuracy, durability and smooth performance. These machines offer many features and solutions to increase your productivity.

All castings and main structure are stress relieved during the manufacturing process to ensure stability of the machine structure and prevent deflection under load. Massive one-piece vertical cast column is heavily ribbed for rigidity with L.M GUIDEWAYS & BALL SCREW

Cast spindle slide is precisely fit for smooth down feed. Latest “Extra Heavy Duty DOUBLE WALL” vertical column for zero deflection & highest stability for CNC machines. The base of the grinder is expanded for the purpose of increasing the supporting capability & stability of the machine.

The Longitudinal table is hydraulically powered and is mechanically noise free. Table speed & stroke are infinitely variable and can be easily adjusted for increased convenience of operation. Hand scrapped and turcite coated for absolute flatness and high wear resistance.

High rigidity spindle preloaded with bearings which provides quiet, vibration- free operation for better work piece accuracy & surface finish. The cartridge type spindle is inter changeable for easy maintenance and field replacement. Moreover spindle bearings are grease sealed to prolong service life special 110MM DIA size.

The cross table travels on hardened and ground LM GUIDEWAYS to ensure smooth, easy movement of table for better quality surface finish and longer way life with SERVO MOTOR

A tidy concise electrical cabinet is designed with low-voltage control for double protections and easy maintenances. All switches are located at the control panel for easy and convenient operation with touch screen panel. The machine is equipped with a PLC control, colour touch screen and a user friendly interface. Operator can simply set up the grinding amount and be ready to start a grinding cycle.

Auto lubrication system is provided for independent lubrication of full machine for longer life accuracy.

AC SERVO MOTOR is providing high accuracy & convenient operating for both vertical & cross.

| DESCRIPTION | SPECIFICATIONS |

|---|---|

| Max. Table Grinding | 300 x 1000 |

| Max. Table Travel | 350 x 1025 |

| Max. Distance Center of Spindle to Table | 325 |

| Total Max. Safety Table Load (approx.) | 275 kg |

| Table Speed (approx.) | 15 M/min |

| Auto Cross Feed Increment (approx.) | 0.2-10 mm/rev |

| Rapid Power Cross Feed | 300 mm/min |

| Cross Feed on Hand Wheel | 5 mm/rev |

| Rapid Power Hand Elevation | 250 mm/min |

| Vertical Feed on Hand Wheel | 5mm/rev |

| Auto Down Feed | Servo Controlled |

| Wheel Speed | 2000 rpm |

| Wheel Dimension (L x W x H) | 300 x 40 x 76.2 |

| Spindle Motor | 7.5 HP |

| Hydraulic Pump Motor | 2 HP |

| Auto Cross Feed Motor | 0.25 HP |

| Rapid Head Elevation | Servo Powered |

| Coolant Pump (optional) | 0.25 HP |

| Machine Net Weight (approx.) | 2800 kg |

| Machine Dimension (L x W x H) | 82 x 70 x 85 inch |

Note: For constant development we reserve the rights to change any technical specifications and design without prior notice.